Our Services

We specialize in reverse engineering and collaborative customer partnerships. From concept to completion, our tailored approach and state of the art CNC machinery ensure precision, quality, and efficiency in every project.

-

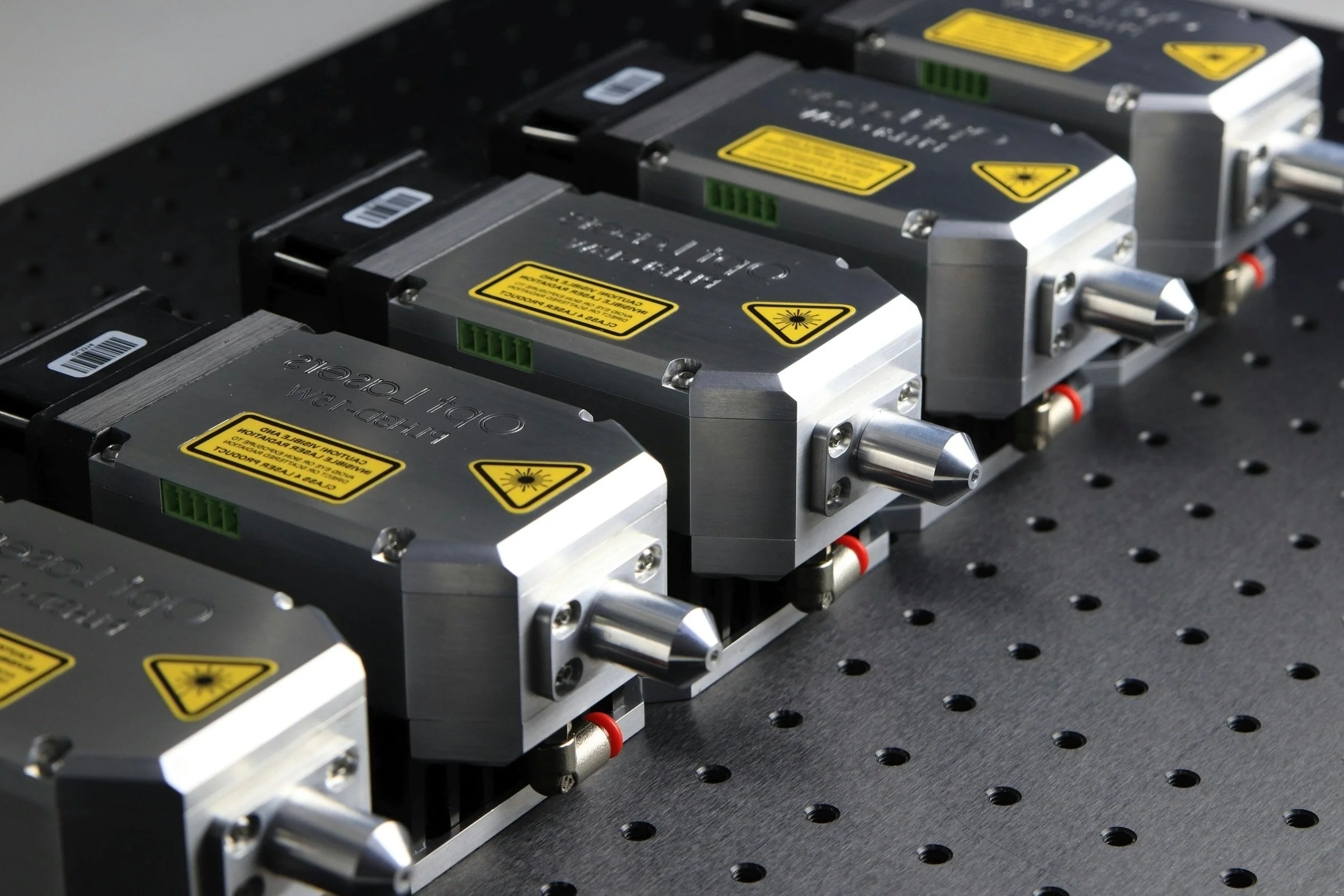

We have (3) high powered state of the art laser cutting machines with 60” X 120” laser tables, equipped with automation.

WHAT WE CUT:

Mild steel up to 1” thick

Stainless steel up to ½” thick

Aluminum up to ¼” thick

-

We have (3) state of the art three state of the art 9-axis press brakes provide precision ground tooling and auto crowning for reliable and precision repeatability from the 1st part to the last.

WHAT WE FORM:

Materials up to 144” long

-

We have a wide range of welding services to meet our customer's requirements through MIG and TIG applications.

WHAT WE WELD:

Mild steel

Stainless steel

Aluminum

-

Shearing- ¼” x 144” wide mild steel capacity

3/16” x 144” wide stainless steel capacity

Rolling

Material polishing and graining

Drilling, tapping, countersinking

Hardware setting

Sawing

Are you in need of full product assembly?

At BP Precision, we offer more than just parts, we deliver comprehensive solutions. Our full product assembly services take your project through every step of the production process, from idea to finished product. Whether you're starting with a rough sketch or a detailed plan, our team is equipped to bring your vision to life.

From Concept to Completion:

Design & Engineering: Utilizing state-of-the-art CAD software and SolidWorks, our team transforms your concepts into precise, workable designs.

Production: From laser cutting to forming, welding to polishing, we ensure that each component is fabricated with accuracy and quality.

Great communication & quick responses, They always go the extra step.

“We have worked with BP Precision for over 20 years - whenever orders need to be expedited, they always make the extra effort to ensure we meet our deadlines and the parts are made correctly the first time.”

- Client Testimonial

A Look At Our Work

Stainless Steel

T-304 Tool Tray

-

Engineering and CAD/Solidworks Product layout

Laser cut

Form

Hardware installation

Welding

Material polishing and passivation

1 piece

Aluminum Housing

-

Engineering and CAD/Solidworks product layout

Laser cut

Form

Weld and deburr for full product assembly

Intricate Multi-Step Formed Brackets

-

Engineering and CAD/Solidworks product layout

Laser Cut

Multistep forming process

Stainless

Steel Tank

-

Engineering and CAD/ Solidworks Product layout

Laser Cut

Forming

Welding and passivation

Industries We Work With

Let’s Build Something Together

Tell us about your project to schedule a free consultation